Accelerate Automotive Dev Time: Fill Hardware-in-the-Loop Ga

Source: Marc Serughetti

Today automotive control systems are becoming more complex requiring more software content executing on multicore MCUs including advanced processor cores, timers and connectivity.

Automotive control systems developers focusing on powertrain, HEV/EV and chassis/safety applications have an increasing need to accelerate and improve their development process as to ensure they can deliver high quality and reliable software on time. In order to identify opportunity for improvement in the development process, we need to look at the current approaches used in the development of such systems and identify potential gaps and solutions. In this post, we will focus on model-based design through the use of Hardware-in-the-Loop systems.

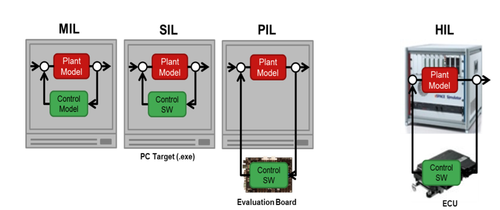

The diagram below highlight 4 currently used ‘in-the-loop’ technologies.

Let’s review these technologies in the context of HW/SW development concerns.

Model-in-the-loop (MIL): model-in-the-loop provides an approach to validate control strategy and algorithm in a simulated environment. This can be done early and tools such as Simulink and SABER have been used extensively in this area. From a HW/SW perspective, there is however no execution of either the embedded software code or the actual microcontroller on which the code will execute.

Software-in-the-loop (SIL): software-in-the-loop provides the ability to use a software representation of the control strategy and algorithm. In this case the software executed is a partial software representation and is compiled for execution on the host PC target. As a result there is no concept of the embedded hardware to be used in the final electronic control unit (ECU) product.

Processor-in-the-loop (PIL): processor-in-the-loop focuses on the use of an evaluation board connected to a host PC executing a plant model. In this context the embedded software is compiled for architectures comparable to the final MCU. PIL still focuses on the control algorithmic implementation, just as MIL and SIL do.

MIL, SIL and PIL can be used early in the design, however they each have limitations when it comes to HW/SW and focus primarily on the control algorithm development and implementation.

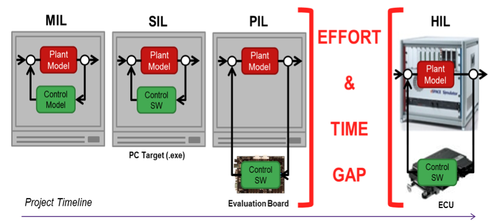

Hardware-in-the-loop (HIL) provides the combination of executing the embedded software on the actual ECU hardware in combination with a model of the physical system (plant). Although this seems like the right environment, transitioning to a HIL environment requires a significant effort, thus creating a gap in the development flow as shown on the following picture:

Click here for larger image.

So what are some of the causes for the gaps and limitations associated with an HIL system? First the complete software stack needs to be integrated, this includes many control functions as well as many software layers including operating system, drivers and middleware. Although the development process has improved over the years, this is still a significant task as the software stack will still need to be debugged to work on the intended MCU/ECU. In addition the tests intended to be used must be developed and integrated in the HIL environment. Once everything is in place, there are still significant limitations associated with an HIL system. They include limited access due to limited numbers of HIL systems (cost and access), limited visibility and controllability of HW and SW, difficulty to deploy in regression and complex to set up, share, maintain and archive. Now that we’ve identified that there is a clear gap in the development process of automotive systems, let’s dive into how we can bridge this gap.

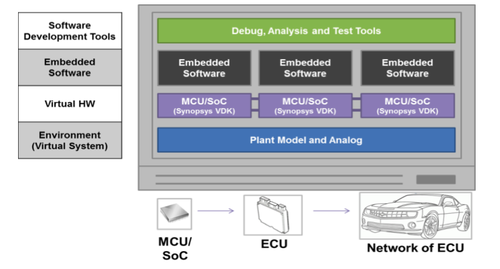

Virtual prototypes and virtual Hardware-in-the-Loop (vHIL) can help bridge this gap. A virtual prototype is a fast simulator of the hardware under development. The virtual prototypes will execute embedded software developed and compiled for the ECU hardware. A system simulation can be executed by co-simulating the virtual prototype on a host PC with analog and plant simulators, thus creating a vHIL environment.

Such an environment provides the following benefits:

Early availability well before the physical hardware is available! Thus enabling the software stack as well as tests to be developed and executed earlier.

Higher productivity. A simulated environment is more easily controlled and provides increased visibility. They also result in a faster understanding of the software and system behavior thus leading to faster debug turnaround time.

Easier accessibility. A simulated environment can be duplicated and shared globally.

The combination of the above benefits lead to more and better testing earlier. Virtual prototypes and vHIL can be used early and in parallel to the algorithmic development supported by MIL and SIL. It bridges the gap to HIL usage and also provides a complementary and scalable environment that accelerates the testing of automotive systems.

Virtual Hardware-in-the-Loop (vHIL) environments are successfully deployed today in the industry. To learn more about vHIL you can download the paper Virtual Hardware "In-the-Loop": Earlier Testing for Automotive Applications: http://www.synopsys.com/cgi-bin/proto/pdfdla/pdfr1.cgi?file=virtual_hardware_wp.pdf as well as the automotive chapter of the Better Software. Faster! ebook at http://www.synopsys.com/Prototyping/VirtualPrototyping/vp-book/Pages/download-vp-book.aspx

―Marc Serughetti is the director of business development and drives the development and deployment of virtual prototyping technologies at Synopsys. He has more than 15 years experience in embedded software development technologies from having led product marketing teams at Integrated Systems, Wind River and CoWare. At CoWare, he led the company into the area of virtual prototyping targeting the embedded software community. His experience spans simulation technologies, compilers, IDE, debugging and analysis tools as well as embedded run-time software (Operating Systems, middleware and applications).

| }

|